Manufacturing

22% of our total CO2 emissions

Manufacturing in Sweden

BAUX products are produced and manufactured in Sweden. However, we have established local factories in USA and Australia to shorten lead times and reduce transportation emissions. As a product-based company, manufacturing will always play a significant role in our total CO2 emissions. Today, 75% of our factories run on renewable energy. We aim to increase this number to 100% in the next five years.

BAUX has manufacturing plants located in Sweden, the USA and Australia.

Having local factories reduces our total CO2 emissions and leads to less emissions incurred from transportation of products to our customers.

All factories, besides our factory in the USA, run on 100% renewable energy.

The factory in the USA is run on natural gas. Our ambition is to move away from the usage of natural gas as soon as an alternative is practical.

The Australian factory is already compensating for their emissions, which is the reason behind their low CO2 value.

Other manufacturing

Pallets for shipping

0.03 kg

When shipping our products around the world, we use pallets. Per 1 square meter of produced product, we have to take the pallets into consideration. The pallets adds a total of 0.03 kg of CO2 per m2 of product, which is a relatively small emission.

Product samples

0,1 %

Sending out samples stands for 0,1 %of our total emissions. We do not want to send fewer samples since they are important for our customers. Instead we ensure that all samples are long lasting, reusable and sustainable.

BAUX Acoustic Wood Wool

BAUX wood fibres are FSC® and PEFCTM certified –– guaranteeing that they can be traced back to responsible forestry operations. The wood is collected from the Swedish forest in the direct surroundings of the factory in order to minimise negative CO2 emissions caused by longer transport distances. The small amount of wood waste that is generated as a result of production is taken care of—80% is used to heat the factory and drying plant. No waste is produced from the timber log.

CO2 emissions kg/m2

Raw Materials

- Wood, cement and water.

- We use locally harvested FSC certified pine and spruce from Swedish forests.

- We use 100% natural materials with no additives.

- Our cement provider, Cementa, has been recognised as the world’s most sustainable cement factory. Read more about this under ‘Installation & End of life.’

Manufacturing

- Sweden, the USA and Australia.

- The raw materials we use are produced in Sweden, in our factory that runs on 100% renewable energy.

- We use low waste production methods.

- We have production plants in the USA and Australia to ensure the final parts of the manufacturing process take place closer to our end customers.

Transport

- From factories to the end client, this includes samples and the final product. This is a weighted average taking all deliveries during 2022 into consideration.

- We aim to produce as few emissions as possible during the transportation of products.

- We transport products to clients on the ground by truck, and rarely use air transportation.

- We have an efficient raw materials logistics solution that provides materials to the USA and Australia.

Installation & End of life

- Installed wood wool products lead to reduced energy consumption due to their heat accumulating performance.

- All wood wool products have a long life and fifty-year warranty.

- Wood wool captures a significant amount of CO2 from the atmosphere, leading to reduced CO2 emissions.

- The recycling process Circle allows clients to return outdated panels as raw materials for new production.

kg CO2e per m2

Wood: 0,05

Cement production: 8,99

Cement carbon capture: -6,29

Packaging materials: 0,01

Raw materials total emissions: 9,04

kg CO2e per m2

Manufacturing Total: 4,88

kg CO2e per m2

From factory to end clients: 8,28

%

% of carbon capture: -70%

This means that we have a 70% reduction in the total CO2 created from wood wool cement production.

BAUX Acoustic Pulp

The Raw materials that Acoustic Pulp is made from are very low in kg CO2e per m2, when compared to corresponding materials on the market (Cellulose, Wheat Bran, Potato Starch and Plant Wax). We take pride in our materials, and Acoustic Pulp is definitely not an exception!

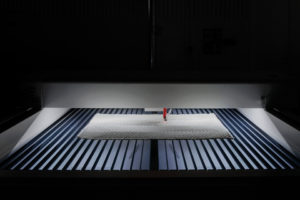

The Acoustic Pulp manufacturing process is highly sustainable and technological.

CO2 emissions kg/m2

Raw Materials

- Cellulose, potato starch, wheat bran and plant wax.

- We use organic and locally harvested cellulose and the wheat bran is a rest product.

- The wood we derive our cellulose from is FSC

Manufacturing

- The factory is run on hydropower.

- 100% renewable energy sources are used for production.

- There is zero waste produced during production.

Transport

-

From factories to the end client, including samples and the final product.

-

We aim to produce as few emissions as possible during the transportation of products.

-

We transport products to clients on the ground by truck, and rarely use air transportation.

Installation & End of life

- Acoustic Pulp is the world’s first biodegradable acoustic panel.

- The panels are 100% circular, and used panels may be moulded and used for reproduction.

- The recycling process Circle allows clients to return outdated panels as raw materials for new production.

k.CO2e per m2

Wood/pulp: 0,44

OC-BioBinder™: 0,249

Raw materials total emission: 0,5

kg CO2e per m2

Sweden: 2,10 (Renewable energy: Yes)

kg CO2e per m2

From factory to end clients: 1,08

BAUX Acoustic Felt

It is challenging to provide an exact value for the carbon dioxide (CO2) emissions associated with recycled PET throughout the entire supply chain, as it involves multiple stages, including collection, sorting, cleaning, reprocessing, and distribution. Additionally, the carbon footprint can differ between different recycling facilities and regions due to variations in energy generation and transportation methods.

That being said, studies have estimated that recycling PET can save around 30-60% of CO2 emissions compared to producing virgin PET. This reduction is primarily due to the avoidance of extracting and processing new fossil fuel resources, as well as the energy savings during the recycling process.

To calculate a fair number of our Co2 for Felt – Recycled PET, we have used an average of the kg CO2e per m2 of Wood Wool & Pulp.

CO2 emissions kg/m2

Raw Materials

- 100 % PET whereof 60-65 % Post Consumer Recycled content Oeko – Tex Standard 100, class I

100 % Recyclable. - GRS Certified source of recycled PET Accredited by IOAS

Source: Recycling entities across Europe

Manufacturing

-

The factory is environmentally certified according to ISO 14001.

-

The water-jet cutting of different panel sizes is made with minimal waste.

-

Investment in R&D projects dedicated to advancing the development of PET recycling.

Transport

- From factories to the end client, including samples and the final product.

-

We aim to produce as few emissions as possible during the transportation of products.

-

We transport products to clients on the ground by truck and rarely use air transportation.

Installation & End of life

-

We approach sustainability in everything we think and do daily. This commitment does not end even when the acoustic products have reached the end of their useful life. That’s why we make it easy for you to have a positive impact on the environment while upgrading your space at the same time. Our Circle will support you all the way.

kg CO2e per m2

PET: 4,7*

kg CO2e per m2

Sweden: 3,5 *

kg CO2e per m2

From factory to end clients: 5*

* To calculate a fair number of our Co2 for Felt – Recycled PET, we have used an average of the kg CO2e per m2 of Wood Wool & Pulp.

Other

Employees and business travel

-

All employees are offered the option to purchase a discounted bike for their office commute.

-

We offer flexible work hours, and all employees receive generous health benefits to spend on either a gym card or massages.

-

We walk, bike and take the tube to meetings. If we drive, we do so electric cars

Our office

- We have a central office location in Stockholm, giving all our employees the possibility to easily walk, cycle or commute to the office.

- Our office runs on 100% renewable energy and we try to use the space as effectively as possible.

Fairs and fair stands

- When showcasing the BAUX brand and products at fairs and events, we aim to reuse materials whenever possible.

- We borrow or rent furniture and products from our friends and colleagues in the industry to reduce both CO2 and money spent.

Total CO2: 2,0 of total CO2

Our office: 0,07 of total CO2

Fairs total CO2: 0,07 of total CO2